Running Towards My Doctor of Medical Science Degree – Ashley Reasey

Physician assistant Ashley Reasey writes about how her passion for trail running helped her succeed in the Pitt DMSc program.

Read More

Finding Language and Friendship through the Aphasia Support Group

The Aphasia Support Group was founded by SHRS faculty as a space to build community and provide social interaction for this population.

Read More

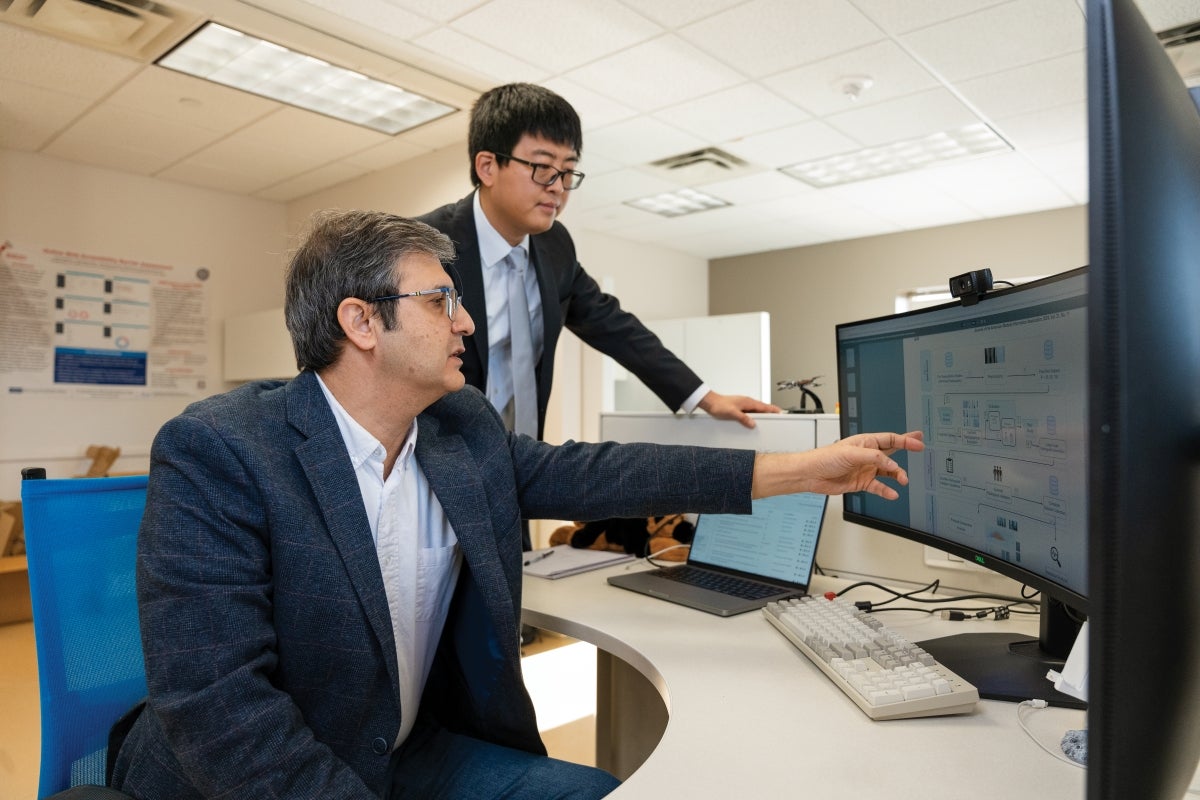

Health Informatics Faculty Help Drive $10 Million Leidos Partnership for Using AI Tools in Health Care

Assistant Professors Ahmad P. Tafti and Yanshan Wang are contributors to Pitt’s Computational Pathology and AI Center of Excellence (CPACE), which announced a $10 million partnership with the technology company Leidos to advance AI in health care.

Read More

Health Informatics Careers are Taking Off

Health Informatics professionals are essential for managing and analyzing health care data, driving breakthroughs in disease prevention, treatment and the discovery of potential cures.

Read More

Pitt Doctor of Medical Science Alumna Reflects on Her Capstone Project

Pitt Doctor of Medical Science alumna Megan McGrane shares about her capstone project focused on advanced practice providers.

Read More

Doctor of Audiology Student Catherine Dymowski Shares How the TRANSLATES Program Helped Develop Her Research Skills

Doctor of Audiology student Catherine Dymowski shares about her experience in the TRANSLATES program.

Read More